1000KN Steel Rebar Universal Tensile Testing Machine

- Ingcaciso yeMveliso

Electro-Hydraulic Servo /Microcomputer Universal Testing Machine

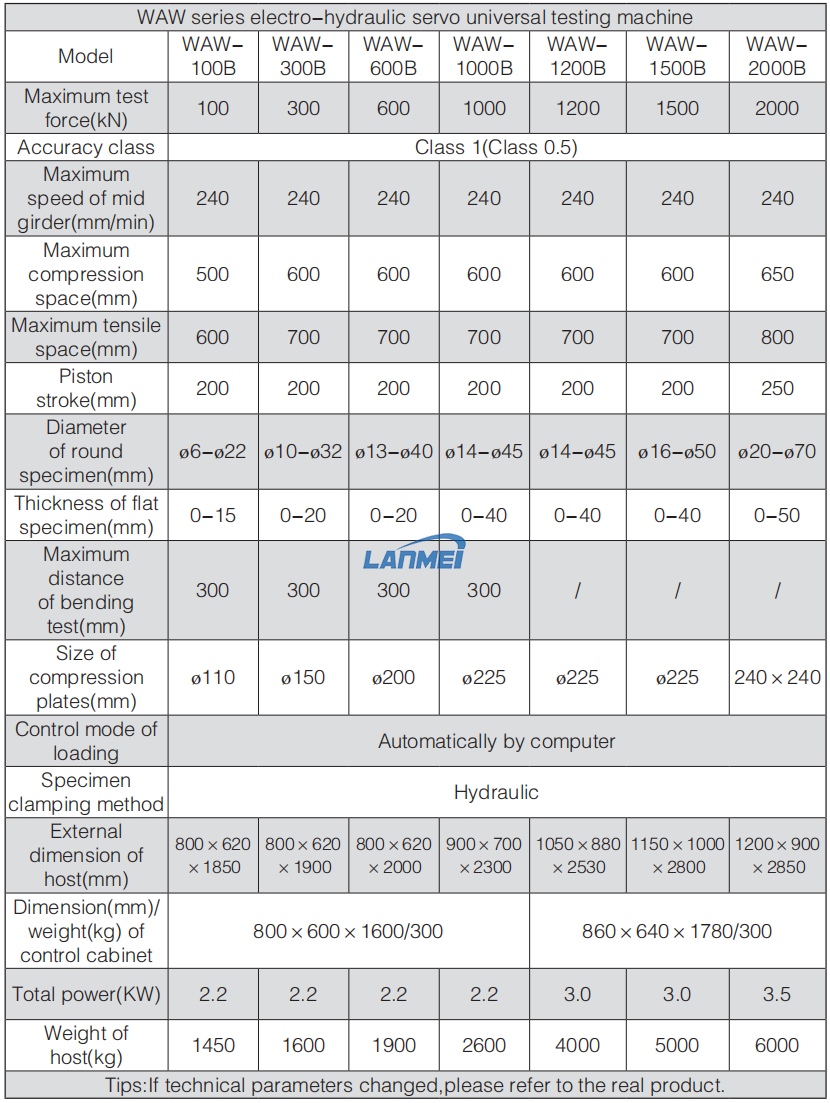

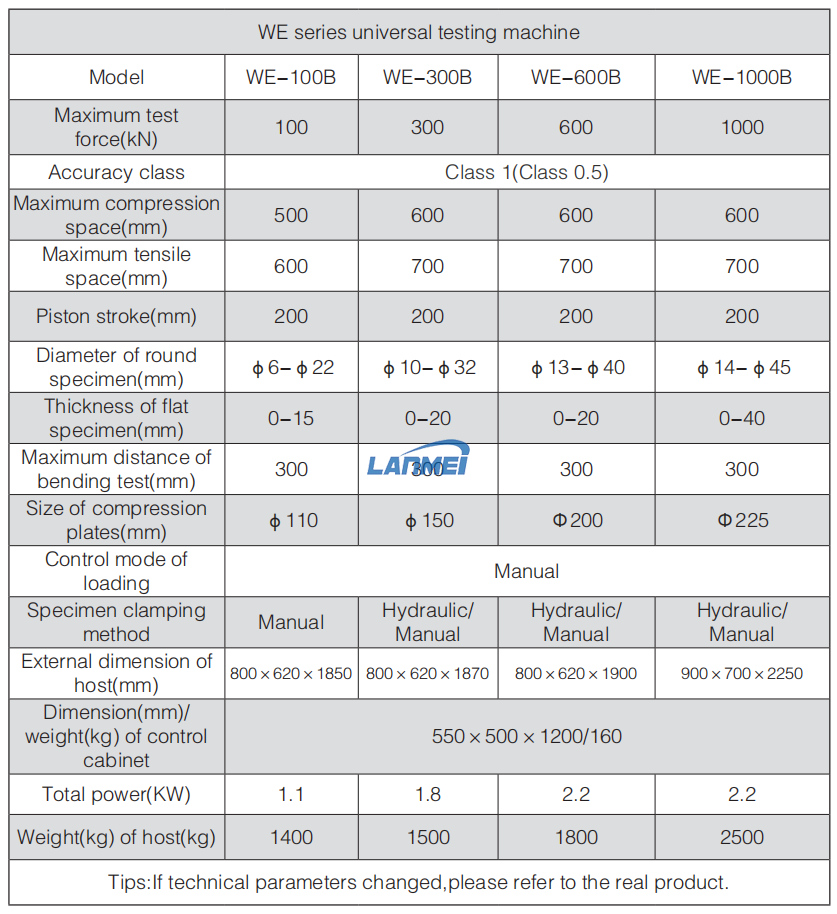

Uchungechunge lwe-WAW lwe-electro-hydraulic servo umatshini wokuvavanya umhlaba wonke lusekwe kwi-GB/T16826-2008 "umatshini wovavanyo we-electro-hydraulic servo jikelele," JJG1063- 2010"umatshini wovavanyo we-electro-hydraulic servo universal," GB/T228.1-2010 "izixhobo zetsimbi" -indlela yokuvavanya ukuqina kwiqondo lobushushu begumbi".Ngumatshini wovavanyo wesizukulwana esitsha ophuhliswe kwaye wenziwa ngokusekwe kuloo nto.Olu luhlu lomatshini wokuvavanya lulayishwe ngehydraulic, kusetyenziswa itekhnoloji yokulawula i-electro-hydraulic servo yovavanyo lokuqina, uvavanyo loxinzelelo, uvavanyo lokugoba, uvavanyo lokucheba lwentsimbi kunye nezinto ezingezizo ezentsimbi, bonisa iintlobo ngeentlobo zeegophe, kubandakanya uxinzelelo, ukuguqulwa, ukufuduswa. kunye nenye indlela yokulawula iluphu evaliweyo, inokutshintshwa ngokungenasizathu kumfuniselo.Irekhoda kwaye igcine idatha ngokuzenzekelayo.Idibana ne-GB, ISO, ASTM, DIN, JIS kunye neminye imigangatho.

Iimpawu ze-WAW uchungechunge lwe-electro-hydraulic servo umatshini wokuvavanya jikelele (uhlobo B):

I-1.Uvavanyo lwamkela imowudi yokulawula ngokuzenzekelayo i-microcomputer, kunye nemisebenzi yezinga loxinzelelo, izinga loxinzelelo, ukugcinwa koxinzelelo kunye nokugcinwa koxinzelelo;

2.Yamkela i-high-precision hub-and-spoke sensor ukulinganisa amandla;

3.Inginginya eyamkela ikholamu emine kunye nezikrufu ezimbini zovavanyo lwesakhiwo sesithuba

4.Nxibelelana nePC nge-high-speed Ethernet ujongano lonxibelelwano;

5.Lawula idatha yovavanyo ngogcino-lwazi olusemgangathweni;

I-6.Amandla aphezulu, ukuqina okuphezulu kunye nenetha elihle elikhuselayo lokukhusela ukhuseleko.

Umsebenzi wokuqala kunye nokugunyaziswa

Emva kokugqiba ukufakwa kombane, vula amandla esixhobo, vula isixhobo.Sebenzisa iphaneli yokulawula kwikhabhinethi yolawulo okanye kwibhokisi yokulawula, ukunyusa umjikelo ophakathi umgama othile (ukuba umqadi uyawa, kufuneka uyeke kwangoko ukusebenza kwaye lungisa ulandelelwano lwesigaba samandla), ngoko ngokuhambelana nencwadana, sebenzisa izixhobo ngaphandle komthwalo, ngexesha lokunyuka kwetafile yokusebenza (ayikwazi ukugqithisa ubuninzi be-stroke), nceda uqaphele ukuba kukho into engaqhelekanga, ukuba idosi, kufuneka ukhuphe kwaye uyeke ukujonga, ukulungisa ingxaki;ukuba akunjalo, ukukhulula de ipiston phantsi kwindawo eqhelekileyo, ukuya ekupheleni.

5.Indlela yokusebenza

Indlela yokusebenza yovavanyo lwe-rebar

1.Vula amandla, qiniseka ukuba iqhosha lokumisa likaxakeka liyavela, vula isilawuli kwindawo yolawulo.

2.Ngokungqinelana nomxholo wovavanyo kunye neemfuno, khetha kwaye ufake i-clamp yesayizi ehambelanayo.Ubungakanani besayizi ye-clamp ekhethiweyo kufuneka ibandakanye ubungakanani bomzekelo.Kufuneka kuqatshelwe ukuba ulwalathiso lofakelo lwe-clamp kufuneka

zingqinelane nesalathiso kwi-clamp.

3.Vula ikhompyuter, ungene kwisoftware "TESTMASTER" kwaye ungenise inkqubo yolawulo, uhlengahlengise iiparamitha zovavanyo ngokweemfuno zovavanyo (indlela yokusebenzisa inkqubo yolawulo ibonisiwe "kumatshini wovavanyo wesoftware manual")

4.Vula ucingo, cofa iqhosha elithi “khulula umhlathi” kwiphaneli yokulawula okanye kwibhokisi yokulawula isandla, kuqala uvule umhlathi ongezantsi, ubeke umfuziselo emhlathini ngokweemfuno zomgangatho wovavanyo kunye neesampulu ezisisigxina emhlathini, vula umhlathi ongaphezulu, cofa iqhosha elithi "ibhanti ephakathi iyanyuka" ukunyusa isiqu esiphakathi kwaye ulungelelanise indawo yesampulu kumhlathi ongasentla, xa indawo ifanelekile ukuvala umhlathi ongaphezulu.

5.Vala ucingo, nciphisa ixabiso lokufuduswa, qalisa umsebenzi wovavanyo (indlela yokusebenzisa inkqubo yokulawula iboniswe "kwincwadana yovavanyo yomatshini wesoftware").

6.Emva kovavanyo, idatha irekhodwa ngokuzenzekelayo kwisistim yolawulo, ize isete umxholo oprintiweyo kwisoftware yesistim yolawulo ukwenzela ukuprintwa kwedatha (indlela yokuseta iprinta iboniswe kwi-"test machine software manual").

7. Susa umboniso ngokwemfuno yovavanyo, cima ivalve yonikezelo kwaye uvule ivalve yokubuya (iimodeli zothotho lweWEW) okanye ucinezele iqhosha elithi “yeka” kwisoftware (WAW/WAWD uthotho lweemodeli), buyisela isixhobo kwindawo yayo. imo yoqobo.

I-8.Yeka isofthiwe, vala ipompo, vala umlawuli kunye namandla amakhulu, Sula kwaye ucoce intsalela kwi-worktable, i-screw kunye ne-snap-gauge ngexesha lokuphepha ukuchaphazela iindawo zokuhambisa izixhobo.

6.Ukugcinwa kwemihla ngemihla

Umgaqo wesondlo

1. Ngalinye ixesha ngaphambi kokuba uqalise umatshini nceda ujonge ukuba kukho ukuvuza kweoli (iindawo ezithile ezifana ne: umbhobho, ivalve yokulawula nganye, itanki yeoli), nokuba ibholiti ibotshelelwe, ingaba umbane ulungile;khangela rhoqo, gcina ingqibelelo yamacandelo ayo.

2.Xa ugqiba uvavanyo ngalunye piston kufuneka iwiswe kwindawo esezantsi, kunye nentsalela ecocekileyo ngexesha, worktable unyango anti umhlwa.

3.Ukusebenza emva kwexesha elithile, kufuneka ube nokuhlolwa okufunekayo kunye nokugcinwa kunye nomatshini wokuvavanya :coca i-residu efana neentsimbi kunye ne-rust kwi-sliding surface ye-clamp kunye ne-girder;khangela ukuqina kwekhonkco kwisiqingatha ngasinye sonyaka;uthambise iindawo ezityibilikayo rhoqo, upeyinte iindawo ezirusa lula nge-oyile ye-anti rust, hlala ucocekile kwaye uchasene nomhlwa.

4.Ukunqanda kubushushu obuphezulu, kumanzi kakhulu, uthuli, i-corrosive medium, isixhobo sokukhukuliseka kwamanzi.

5. Faka endaweni yeoyile yehydraulic ngonyaka okanye eyongezelekayo emva kokusebenza iiyure ezingama-2000 .

6.Musa ukufaka enye isoftware kwikhompyuter, ukuthintela ukwenza isoftwe yenkqubo yovavanyo isebenze ngokungaqhelekanga;thintela ikhompyutha kusulelo lwentsholongwane.

7.Ngaphambi kokuba uqalise umatshini kufuneka ukhangele ukuba ngaba intambo yokudibanisa phakathi kwekhompyutheni kunye nomninimzi kunye nesokethi yeplagi yamandla ichanekile okanye ikhulule, unokuqalisa emva kokuqinisekiswa kokuchanekileyo.

8.Nawuphi na umzuzu awukwazi ukutshisa iplagi yombane kunye nomgca wesignali, ngaphandle koko kulula ukulimaza into yokulawula.

9.Ngexesha lovavanyo, nceda ungacinezeli ngokungqongqo iqhosha kwipaneli yekhabhinethi yokulawula, ibhokisi yokusebenza kunye nesofthiwe yokuvavanya.Ungaphakami okanye uwele i-girder ngexesha lovavanyo.Musa ukufaka isandla sakho kwindawo yovavanyo ngexesha lovavanyo.

10.Ngexesha lovavanyo, musa ukuchukumisa izixhobo kunye nazo zonke iintlobo zekhonkco, ukwenzela ukuba ungachaphazeli ukuchaneka kwedatha.

11. Njalo khangela utshintsho lwezinga letanki yeoli.

12.Khangela ukuba umgca wokudibanisa umlawuli unxibelelana kakuhle rhoqo, ukuba ukhululekile, kufuneka uqiniswe ngexesha elifanelekileyo.

13.Emva kovavanyo ukuba isixhobo singasetyenziswanga ixesha elide, nceda uvale amandla aphambili, kwaye kwinkqubo yokumisa izixhobo zisebenza izixhobo zokungabikho komthwalo rhoqo, ukwenzela ukuba kuqinisekiswe xa izixhobo zisetyenziswa. kwakhona, allperformance indexes ziqhelekile.

Iingcebiso ezikhethekileyo:

1.Sisixhobo sokulinganisa ngokuchanekileyo, kufuneka ibe ngabantu abakwizikhundla ezisisigxina kumatshini.abantu abangenalo uqeqesho banqatshelwe ngokungqongqo ukusebenzisa umatshini.Xa umphathi eqhuba, umqhubi akafanele ahlale kude nesixhobo.Kwinkqubo yovavanyo lokulayisha okanye ukusebenza, ukuba kukho nayiphi na imeko engaqhelekanga okanye ukusebenza okungalunganga, nceda ucofe ngokukhawuleza iqhosha elibomvu lokumisa likaxakeka kwaye ucime amandla.

2.Fasten i-nut kwi-screw yohlobo lwe-T ye-bearing bearing phambi kovavanyo lokugoba, ngaphandle koko kuya kulimaza i-clamp egoba.

3.Ngaphambi kovavanyo lokwelula, nceda uqinisekise ukuba akukho nto kwindawo ecinezelweyo.Akuvumelekanga ukwenza uvavanyo oluzolula ngesixhobo sokugoba, kungenjalo kuya kubangela umonakalo omkhulu kwisixhobo okanye kwingozi yokwenzakala.

4.Xa ulungelelanisa indawo yokugoba ngebhanti kufuneka uhlawule kakhulu kumgama we-specimen kunye ne-roller yoxinzelelo, akuvumelekanga ngokungqongqo ukunyanzela umboniso ngokuthe ngqo ngokunyuka okanye ukuwa kwe-girder, kungenjalo kuya kubangela umonakalo omkhulu kwisixhobo. okanye ingozi yokwenzakala komntu.

5.Xa isixhobo sifuna ukushukuma okanye ukudilizwa, nceda umaka kwangaphambili umbhobho kunye nesekethe yombane, ukwenzela ukuba iqhagamshelwe kakuhle xa iphinda ifakelwe;xa isixhobo sifuna ukuphakanyiswa, nceda uwele i-girder phantsi kweyona ndawo iphantsi okanye ubeke iinkuni eziqhelekileyo phakathi kwebhanti kunye netafile yokusebenzela (ok. Kufuneka kungabikho imvume phakathi kwebhanti kunye netafile yokusebenzela ngaphambi kokuba uphakamise umkhosi), kungenjalo ipiston ilula ukukhupha kwi-cylinder, kukhokelela ekusebenziseni okungaqhelekanga.

-

I-imeyile

-

Wechat

Wechat

-

Whatsapp

whatsapp

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur