Ukulawulwa kwe-serso ye-Servo yoVavanyo lweZinto zeRester

- Ingcaciso yeMveliso

Ikhompyuter yekhompyuter ye-hydraulic sport

I-1.Malters ifuna ingqalelo

Nceda ufunde le ncwadana ngenyameko ngaphambi kokusebenzisa esi sixhobo, kwaye uyigcine kwiinjongo zexesha elizayo

Iimfuneko zokuhlala

① I-Heard Revym Resort 10 ℃ ~ 35 ℃

② the theaids ongekho ngaphezulu kwe-80%

Akukho ntshukumo, akukho lusulelo, akukho simo sokuphazamiseka kwe-electromagnetic

④ Inqanaba alifaneki ngaphezulu kwe-0.2mm / 1000mm

⑤ kufuneka ijikeleze indawo ye-0.7m, izixhobo kufuneka zibe selokwana ngokuthembekileyo.

Iimfuno zamandla

Esi sixhobo sisebenzisa i-380V yesigaba se-380V yesigaba se-4 (ukongeza kwezinye iingcebiso), uzinzo lwevoli, musa ukugqitha kwi-± ± ye-± ye-10A.

Iimfuneko ze-Hydraulic

Izixhobo zamkela i-hydraulic oyile njenge-fluid ye-fluid: Xa ubushushu begumbi ngaphezulu kwe-25 ℃, kusetyenziswa i-No.68 ioyile ye-hydraulic. Xa ubushushu begumbi bungaphantsi kwe-25 ℃, usebenzisa i-No.46 Anti-nxiba ioyile ye-hydraulic.

Ebusika, xa ubushushu begumbi buphantsi kakhulu, emva kokuguqula umatshini nceda izixhobo zokuhlala (qala impompo yeoyile) kwimizuzu eli-10. Xa kusetyenziswa rhoqo, ioyile ye-hydraulic kufuneka itshintshwe isiqingatha sonyaka, nokuba itanki yefutha kunye nefilitha kufuneka icoceke okanye ingagqitywanga ngumgangatho wongcoliseko.

Esi sixhobo asinakusebenzisa ioyile yenjini, ipetroli okanye enye ioyile endaweni yoko. Ukusilela kwecandelo le-hydraulic ngenxa yeoyile engalunganga, ayiyi kubandakanywa kumda wewaranti.

Malunga nokumisa ngexesha likaxakeka

Kwimeko yexesha likaxakeka ngexesha lokufakwa, ukusebenza, njengoko iivalves zodwa azikwazi ukukhupha, ukusebenza okungaqhelekanga kwemoto, enokubangela umonakalo kumatshini okanye ekonakaleni kwe-tester, nceda ucime umatshini wesekethe.

Ukuchaneka

Izixhobo zilungelelaniswe ngokuthe ngqo ngaphambi kokuba bashiye umzi-mveliso, musa ukuziqhelanisa neeparameter. Impazamo yokulinganisa inyuka ngenxa yohlengahlengiso olungagunyaziswanga lweeparamitha zokulinganisa, aziyi kubandakanywa kumda wewaranti. Ungaqhagamshelana neSebe lendawo yokujonga eMgangathweni yendawo ukuze ufumane ububi ngokwenqanaba lokunyanzelwa kwezixhobo.

Amandla aphezulu

Chonga uluhlu lwezixhobo ngokweebheli ezixhobo, udidi lokulinganisa luhlengahlengiswe kumzi-mveliso, ungatshintshi iParameter yoluhlu olunokubangela ukonakaliswa kwexabiso lezinto ezinokuthintela iiparaments ze-rameter, ayizukubandakanywa kumda wewaranti.

2.Geta kunye Intshayelelo

Ungcelele we-Whow Lowro-Hydraulic senso reminaral yovavanyo

I-Worpolic Senso-Hydraulic senso reminary yovavanyo isekwe kwi-GB / T16826-2008 yomatshini wokuvavanya i-Electro Universion ". Umatshini wovavanyo ulayishwa nge-hydraulic, usebenzisa itekhnoloji yolawulo lwe-elenro-hydraulic ye-Conser, kuvavanyo lwe-consile, kubandakanya uxinzelelo lwe-isoop, irekhodile kunye nenye i-GB,

I-ISO, i-ASTM, Din, Jis neminye imigangatho.

Amanqaku oMdibano weWew Electro-hydraulic senso winsort yovavanyo lovavanyo (uhlobo b):

① Uvavanyo lumkela i-microcompar yolawulo oluzenzekelayo, kunye nemisebenzi yexabiso loxinzelelo, ireyithi yotywala, ukugcinwa koxinzelelo kunye nokugcinwa kwezinto;

Ukwamkela i-hib-and-procy hib-kunye ne-hub-ethetha intetho ethethayo yokulinganisa amandla;

③ I-Tost i-Tosts, yamkela ikholamu emine kunye neziqwengana eziphindwe kabini kuvavanyo lwendawo

Nxibelelana nePC nge-PC ye-Special Ethernet yoNxibelelwano;

⑤ Ukulawulwa kwedatha yovavanyo ngolwazi oluqhelekileyo;

⑥ Amandla aphezulu, ubunzima obuphakamileyo kunye nomnatha omnandi wokukhusela ukukhusela

4.Khetha kunye nokuyalela

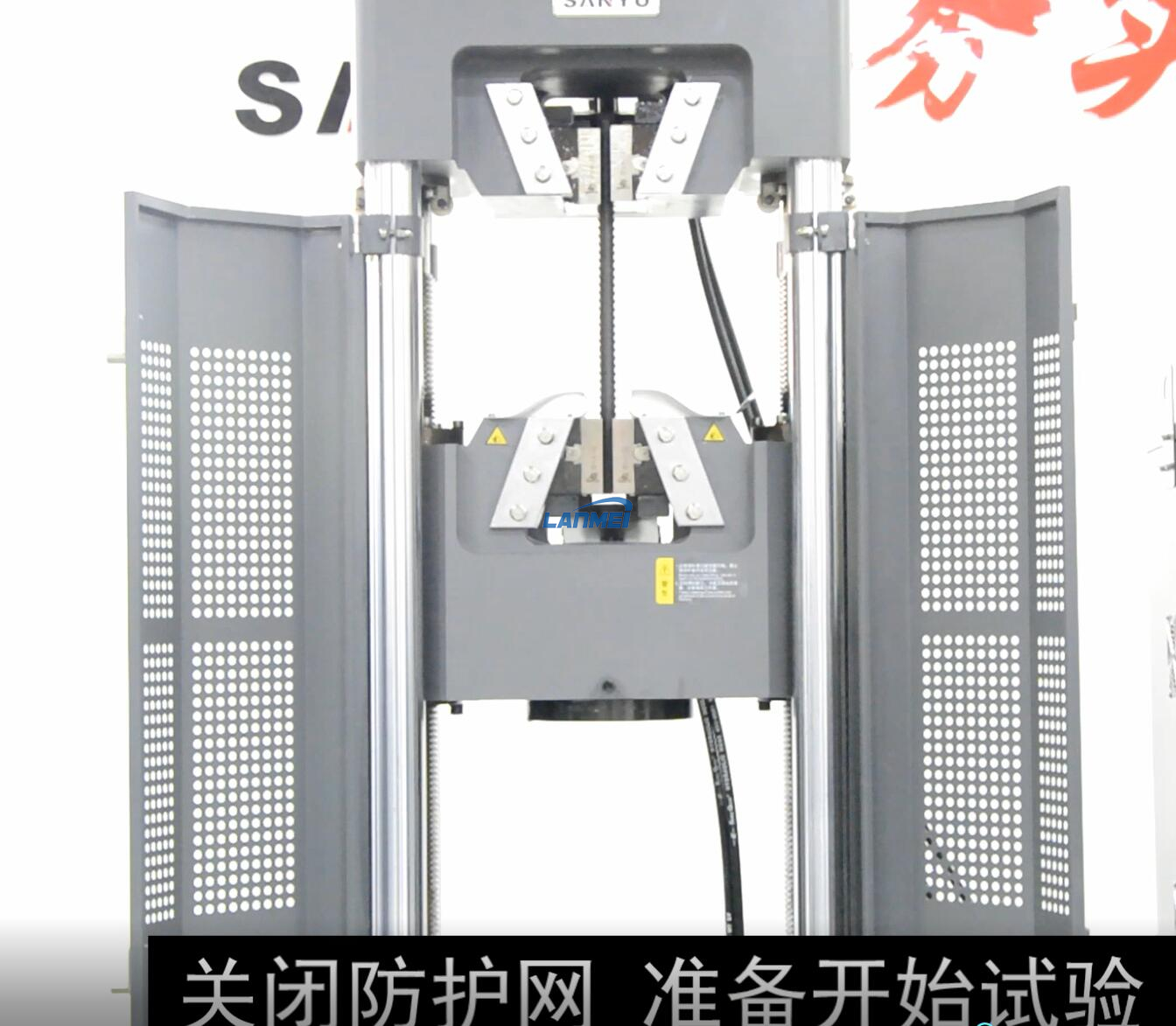

Lungiselela izixhobo zokuFumathela

Jonga izixhobo eziqhotyoshelwe kwizixhobo ngokoluhlu olutshoyo, kwaye ujonge ukuba izincedisi zilungile zilungiselele i-screwddriver, i-spanner ehlengahlengisiweyo kunye neseti ye-Angle yangaphakathi

Lungisa injini ephambili

Lungisa izixhobo ngokweeparamitha ezisisiseko zesalathiso kumzobo wesiseko (jonga imiyalelo ye-HOSE kwi-HOSEPE iPPOPE ye-oyile nceda ulahlekelwe ngumatshini wokuhambisa kwixesha elizayo. Unxibelelwano malube lusondeleyo, kwaye luye kwi-par kwi-washer yokutywina.

Unxibelelwano lwesekethe lweoyile

Gcwalisa isixa esifanelekileyo seoyile ye-hydraulic ngokwephepha letanki yeoyile (linda ubuncinci iiyure ezi-3 ngaphambi kokuba ugcwalise i-injini ye-hydraulic kwi-pipelic the pipelic), xa usenza i-pipeling pipeling, i-gasket enye kufuneka ibekwe phakathi Ipayipile kunye ne-spice, kwaye ibopha i-Wrench, njengoko kubonisiwe iplagi ye-oyile engafakwanga i-hose nceda ube nokukhusela umatshini wexesha elizayo. Xa ususa izixhobo zicela uyikhuphele phantsi imibhobho kwaye uzitywine yiplagi yeoyile.

Unxibelelwano lombane

Thatha phantsi iseti yonke yemigca yedatha, ngokungqinelana nomgca wedatha ehambelana nonxibelelwano kwiKhabhinethi yoLawulo ishiye. Nceda uqhagamshele intambo yamandla ngokuhambelana neleyibhile eqhotyoshelweyo. I-wire ye-null (umgca 4) wenqanaba lesithathu elinesigaba sentambo-wine-wire.

Vula iphakheji yekhompyuter, faka ikhompyuter (eli nyathelo lilungele kuphela iimodeli eziqukethe ikhompyuter); Emva koko faka isiphelo esinye se-RS-232 Umgaqo wonxibelelwano kumlawuli, esinye isiphelo sifaka ikhompyuter. Nceda ungayithathi indawo yekhompyuter kunye nezixhobo. (Iingcebiso: Eli nyathelo alifuneki kuhlobo lwekhompyuter yekhompyuter)

Vula iphakheji yomshicileli kwaye ufake umshicileli ngokwemiyalelo yokufaka eqhotyoshelwe kwiprinta (eli nyathelo lifakwe kwikhompyuter equlathe idiski yangaphandle).

Ukusebenza kokuqala kunye nokuyalela

Emva kokufakwa kombane kugqibile, tshintsha kumandla esixhobo, vula izixhobo zekhabhathi yolawulo okanye kwibhokisi yokulawula umthwalo (ukuba ungayiyeka i-ginser), ungaphezulu kwe-ginsed), nceda uqaphele ukuba kukho into engaqhelekanga, ukuba Idosi, kuya kufuneka ukhuphe kwaye uyeke ukukhangela, ulungisa ingxaki; Ukuba akukhange kubenjalo, ukuthumela kude kube yipiston kwindawo eqhelekileyo, yokugunyazisa iziphelo.

Umzobo wesixhobo